-

Processing and machining of PTFE parts

PTFE is known for it’s stability and resistance to many chemicals. … This makes it a very versatile material, and we mould, form and machine parts in this material. Generally, PTFE is processed into semi-finished shapes with compression or iso-static moulding techniques. The PTFE resi...Read More -

Plastics Processing and Manufacturing,Process of Plastic Extrusion

Plastic extrusion is a process where plastic is melted and formed into a continuous form. This process is used for producing things such as pipe, fencing, tubing, wire insulation, window frames, and railing… Plastics Processing and Manufacturing Plastics are polymers with high molecular wei...Read More -

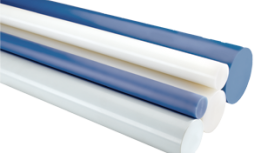

Plastics Make UHMW Rod and UHMW Profiles

Advantages of UHMWPE Rod UHMWPE is odourless, tasteless, and nontoxic, Has extremely low moisture absorption. Very low coefficient of friction… The material is light weight, having a density of .93 – .94, making it lighter than water, thus it will float in water. This lightweight plas...Read More -

Plastic-lined Piping

Metallic pipe is strong, easy to work with and inexpensive, but even mildly corrosive fluids can rapidly eat away at it, from the inside out, severely limiting it’s lifespan. Nonmetallic piping, fiberglass and thermoplastics, does not have the physical strength of metallic piping, but has e...Read More -

PTFE Shaft seals

Where High-Speed Seals Are Found High speed rotary shaft seals are found in many applications. Examples would include cryogenic deflashing equipment, vacuum pumps, torpedo shaft seals, gas turbine engine starters, and submersible dredge pumps. AC/DC motors often require high speed sha...Read More -

Why Choose PTFE lined hose?

What is PTFE? Polytetrafluoroetheylene is the specific chemical name for polymer. PFTE is a special product to make industrial hosing from as it does not breakdown with exposure to corrosive acids, even when hot. It does not dissolve due to solvent exposure; does not become fragile and breakable ...Read More